Overview

Conveyor Belts

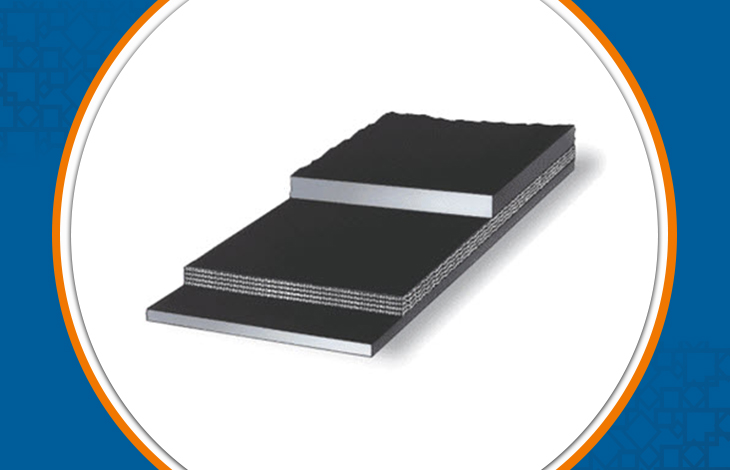

Our branded belts are specifically engineered to meet the stringent specifications of the African market, providing exceptional support for a large client base across the continent, including in the challenging conditions of South Sudan. The multi-ply belts, consisting of four to six fabric layers with a rubber interface, vary in thickness depending on the application. These belts are designed to transport materials in harsh conditions within the bulk material handling industry, and are available with various covers such as abrasion-resistant, oil-resistant, and flame-resistant options.

For over 25 years, our conveyor belts have been the top choice for super quarries and process industries, known for their efficiency, durability, and cost-effectiveness. Crafted from globally sourced materials and designed to withstand the hot, humid, and dusty conditions prevalent in East Africa, these belts have consistently supported regional construction. As the first commercial manufacturer of conveyor belts in East Africa, Rugged Equipment ensures high-quality control and availability. Our belts, made using polyester-polyamide (nylon) fabric plies and rubber covers conforming to DIN 22102 standards, are ideal for bulk handling of heavy and abrasive materials across various industries such as quarrying, stone crushing, cement processing, mining, and more.

Rugged Equipment has made significant investments in advanced technology at our conveyor belt factory, ensuring top-notch quality control through a fully equipped laboratory with precision testing equipment. We continually strive for innovation and quality to meet the high demands for conveyor belts, offering flexibility and responsiveness to customer needs. Our customized specifications cater to specific application requirements, making us a reliable partner in the bulk material handling industry across East Africa.

Belt Tensile | Carcass Weight (kg/m²) | Carcass Thickness (mm) | Minimum Pulley Diameter A | Minimum Pulley Diameter B | Minimum Pulley Diameter C |

EP 500/4 | 5.36 | 4.4 | 500 | 400 | 315 |

EP 630/4 | 5.84 | 4.8 | 630 | 500 | 400 |

EP 800/4 | 6.16 | 4.8 | 800 | 630 | 500 |

EP 800/5 | 7.6 | 6.1 | 800 | 630 | 500 |

EP 1000/4 | 6.86 | 6 | 800 | 630 | 500 |

EP 1000/5 | 8 | 6.1 | 1000 | 800 | 630 |

EP 1250/4 | 7.72 | 6.8 | 1000 | 800 | 630 |

EP 1250/5 | 8.9 | 7.6 | 1250 | 1000 | 800 |

EP 1600/4 | 8.6 | 7.6 | 1250 | 1000 | 800 |

EP 1600/5 | 9.95 | 8.6 | 1250 | 1000 | 800 |

EP 2000/4 | 11.26 | 9.2 | 1400 | 1250 | 1000 |

EP 2000/5 | 11.05 | 9.6 | 1400 | 1250 | 1000 |

EP 2500/4 | 13.24 | 11.6 | 1600 | 1400 | 1000 |

EP 2500/5 | 14.5 | 11.6 | 1600 | 1400 | 1000 |

EP 3150/5 | 17.1 | 14.6 | 1800 | 1600 | 1250 |